Profit margins in the restaurant industry are razor-thin, and every dollar wasted in operations is a dollar lost from the bottom line. Many restaurants unknowingly hemorrhage money through avoidable direct and indirect costs. From food storage mishaps to underused marketing campaigns, these hidden drains can make or break profitability.

This guide highlights 13 of these profit-guzzling culprits and suggests practical strategies for identifying and addressing them. Additionally, it will explore how they affect your cost of goods sold (COGS), via recipe costing and menu analysis, and the ultimate profitability of your offerings.

Direct Costs That Erode Profit Margins

1. Improper Food Storage

Overview: Perishable ingredients require precise storage conditions to avoid spoilage.

Example: A faulty door-closing mechanism causes inconsistent temperatures in your restaurant’s walk-in, and staff doesn’t notice. Several cases of produce wilt before use, reducing ingredient shelf life.

Impact: Wasting $500 per month replacing spoiled inventory cuts into your COGS and affects recipe-costing accuracy. Proper training and regular observations by management can prevent these losses, creating a culture where staff actively monitors storage issues to protect inventory. Time and temperature should be front of mind, especially for the team working in the heart of the house.

2. Overproduction of Food

Overview: Preparing too much food results in waste.

Example: Your restaurant misestimates reservations for Valentine’s Day, resulting in 50 untouched desserts by the end of the evening.

Impact: The $200 wasted in dessert ingredients and unnecessary kitchen labor hours inflates your COGS. Accurate sales forecasting tools can help align production with demand, reducing overproduction and improving menu profitability.

3. Overuse of Ingredients in Recipes

Overview: Generous portions or careless measurements inflate ingredient costs.

Example: Your burger chain’s cooks regularly use an extra slice of cheese per order, deviating from the standard recipe.

Impact: Annual ingredient costs rise by $10,000 across 10 locations. This issue also disrupts recipe-costing accuracy, which in turn impacts your menu-pricing strategy. Training staff on portion control ensures consistency and profitability. Build a culture that emphasizes cross-checking for quality control. Done well, this creates a team that welcomes feedback and proudly strives to produce a consistent product.

4. Poor Cooking Practices

Overview: Cooking errors lead to wasted ingredients.

Example: A newer line cook frequently over-seasons soups, requiring remakes.

Impact: Weekly losses of $100 in ingredients and time spent re-preparing dishes drive up COGS. Consistency in cooking practices ensures accurate recipe costing and maintains customer satisfaction. Pay close attention to the cooks handling costlier proteins, and establish standards and guides that yield consistent products regardless of the chef or the night of the week.

5. Ineffective Inventory Management

Overview: Disorganized inventory leads to expired or forgotten items.

Example: Your pizza kitchen discovers expired mozzarella buried behind fresh stock.

Impact: Monthly losses of $300 in spoiled cheese and replacement costs reduce inventory turnover and skew your COGS. Inventory management software can provide visibility into stock levels and expiration dates, enabling better decision-making for menu analysis.

6. Lack of Employee Training

Overview: Untrained employees are prone to errors that result in waste.

Example: A new bartender mistakenly pours call liquor instead of house spirits for happy hour drinks.

Impact: Higher beverage costs of $250 per month inflate your overall COGS. Comprehensive training ensures that staff understand cost-conscious practices, improving recipe execution and profitability. Train your management team to spend time nurturing newer team members, bringing them up to speed with accuracy and confidence.

7. Carelessness and Spills

Overview: Mishandling items leads to unnecessary waste.

Example: A server drops a tray of cocktails en route to a table.

Impact: Each incident, costing $50 in lost product and replacement glassware, directly affects your margins. Further, the chaos of multiple spills behind the bar and in the kitchen can potentially lead to lost sales. Though accidents, of course, happen, instilling a culture of accountability and care minimizes such losses, helping maintain stable COGS.

8. Improper Trimming and Preparation Techniques

Overview: Over-trimming or discarding usable parts of ingredients reduces yield.

Example: Your sushi chef discards perfectly good tuna scraps instead of repurposing them for spicy tuna rolls.

Impact: A monthly loss of $400 in underutilized product affects ingredient yield and recipe costing. Training chefs on efficient preparation techniques maximizes product usage and improves menu analysis. Create a thoughtful kitchen culture, and be sure your team understands the concept of cross-utilization when it comes to ingredients.

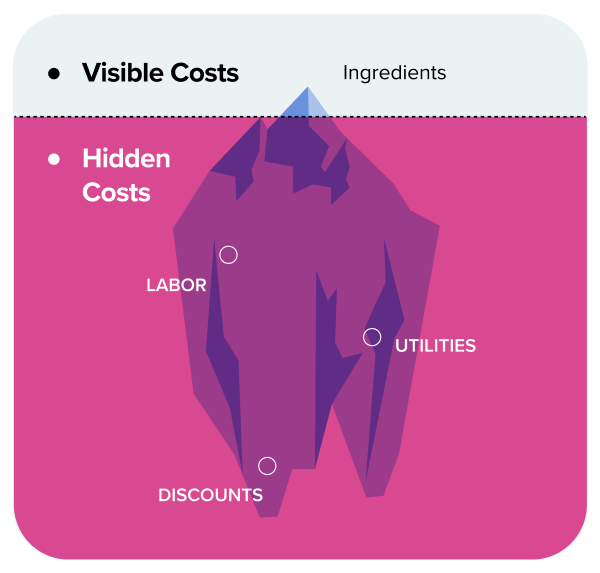

Indirect Costs That Compound Financial Strain

9. Increased Labor Costs Due to Food Waste

Hidden Costs Alert: Food waste isn’t just about ingredients—it’s about the labor required to fix mistakes.

Example: After burning a batch of bread, your team spends extra hours baking replacements.

Impact: An additional $60+ in wages per error adds to operational costs. These inefficiencies also affect recipe costing by increasing the hidden labor associated with dish preparation.

10. Higher Utility Costs from Cooking and Storing Excess Food

Hidden Costs Alert: Storing or cooking unneeded items raises energy consumption.

Example: Your team over-produces chicken wings, requiring prolonged fryer use.

Impact: Monthly utility bills increase by $100, which indirectly affects your COGS. Streamlining production based on demand forecasts can cut unnecessary utility expenses and improve overall profitability. Examine team hours, prep schedules, and patterns in your kitchen to ensure that the team is working as efficiently as possible.

11. Price Discounts to Move Excess Inventory

Hidden Costs Alert: Offering discounts to sell surplus products impacts margins.

Example: Your bakery slashes prices on unsold croissants at the end of each day.

Impact: Revenue drops by 30% for discounted items. Inventory mismanagement affects recipe-costing accuracy and the perceived value of menu items. Regular discounts at the end of the day will also create a cohort of guests that wait, looking for the discount, so it’s best to minimize these instances. Incorporating the excess inventory into another dish is a positive way to utilize product.

12. Additional Marketing Expenses to Avoid Waste

Hidden Costs Alert: Promotions for slow-moving items drain the marketing budget.

Example: Your steakhouse spends $500 on ads and materials to promote an overstock of ribeye steaks.

Impact: Limited ROI cannibalizes higher-margin sales. Thoughtful menu analysis to adjust pricing or repurposing ingredients can mitigate these losses.

13. Reduced Productivity from Waste Management

Hidden Costs Alert: Managing waste takes staff away from serving customers.

Example: A prep cook spends an hour rearranging disorganized stock to account for spoiled items.

Impact: Slower ticket times and lower table turnover negatively impact guest experience. Implementing waste management systems improves efficiency, enabling staff to focus on customer service. These systems also help to instill an inventory-conscious mindset amongst the team.

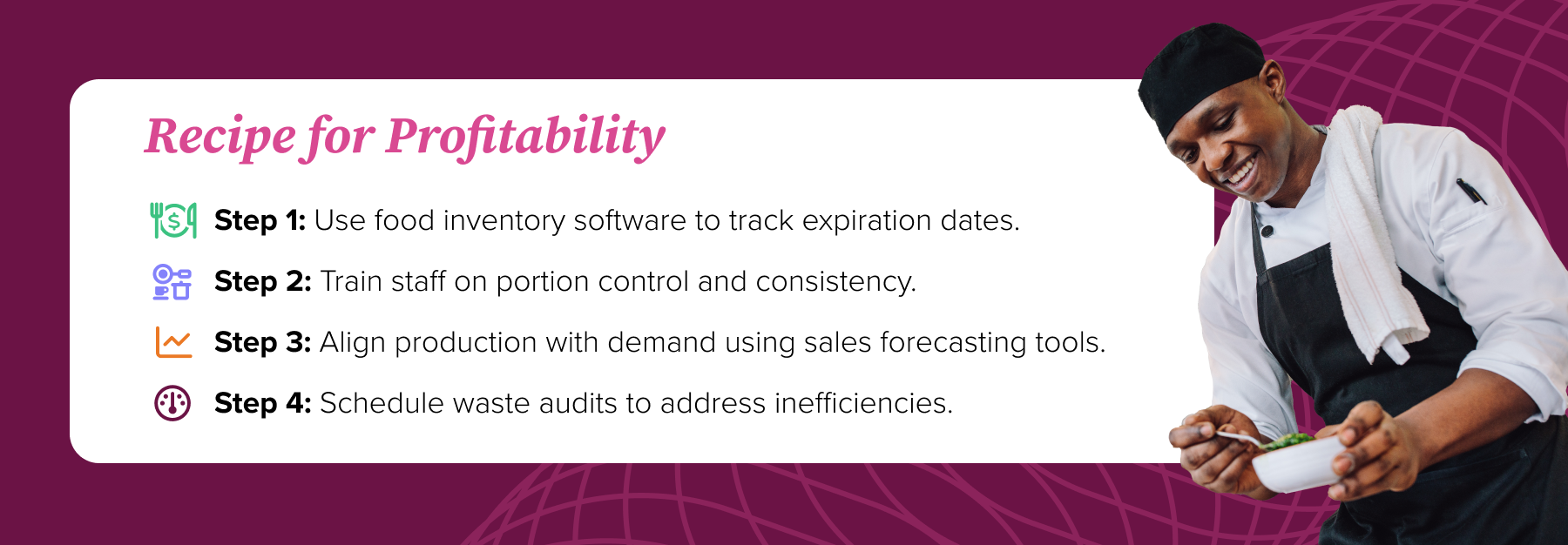

How to Combat These Cost Drains

- Implement Food Inventory Software: Track expiration dates and storage needs to reduce spoilage and maintain accurate COGS.

- Train Employees on Portion Control and Cooking Consistency: Consistent practices ensure accurate recipe costing and reduce waste.

- Use Sales Forecasting Tools: Align production with demand to avoid overproduction and surplus inventory.

- Schedule Waste Audits: Regular audits help identify and address problem areas that inflate COGS.

- Engage Staff in Waste Reduction Strategies: Incentives for improved practices create a culture of accountability and efficiency.

Direct and indirect costs quietly drain profits, but awareness and proactive measures can protect margins. Managing your Cost of Goods Sold through precise inventory management, efficient recipe costing, and regular menu analysis is key to staying profitable. Adopt smart practices and routines with your management team, and leverage technology to prevent these drains and help your bottom line.