Recipe Costing 101

Recipe Costing is not a one-time occurrence – it’s an ongoing process.

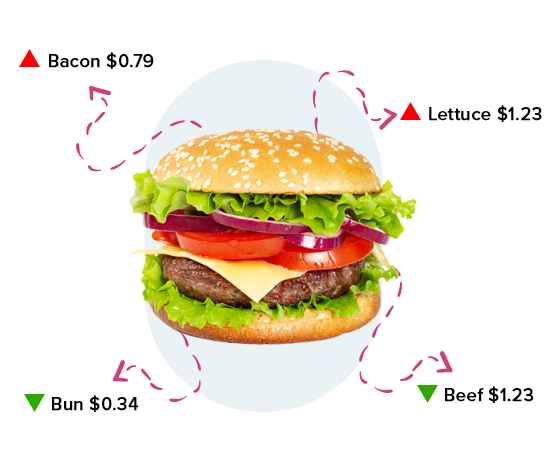

When food costs change, your recipe costs change.

The actual purpose behind plate costing is so that you can price your menu items to ensure you’ll make money.

If you notice a higher food cost than usual you can adjust your selling price, reduce portion sizes or find the same or similar ingredient at a lower cost.

As much as you enjoy the restaurant industry, at the end of the day, you have to make a profit.

So how exactly do you calculate the cost for a recipe?

What is Recipe Costing?

Recipe costing is exactly what it sounds like—calculating the cost of a single item on the menu.

If you’ve ever written a restaurant menu then you know how complicated and time-consuming this process can be.

Plus, if you are like me and not good at math, things just got MUCH harder.

How to Calculate Plate Cost

Calculate your restaurant Plate Costs by following the steps below:

1) Measure out the quantity of each ingredient in a dish (8oz ground beef, 1 bun, 2oz pickles, 1oz ketchup etc.)

2) Calculate the price for each ingredient in the dish. Things get tricky here because you are dealing with different pack sizes and units of measure. Let’s use ground beef as an example.

- Your recipe requires 8oz of ground beef, but when you bought the ground beef, it came in a 5lb package.

- We will need to convert 5 lbs to ounces.

- 16 oz = 1 lb

- 5 lbs x 16 oz = 80 oz

- We now need to determine the price per ounce.

- Since the original purchase cost was $30.00, we simply divide $30.00 by 80 oz, which equals $0.37 per ounce.

- To determine the cost of an 8 oz patty, we simply multiply 8 oz x $0.37 = $3 for our 8 oz burger patty.

3) Complete the following for every item in that recipe and add them together. This equals your plate cost (recipe cost) in a dollar amount.

4) Calculate Food Cost Percentage

- Food Cost Percentage Formula = (Recipe Cost / Selling Price) x 100

Next, you will have to do this for EVERY item on your menu!

Who’s got time for that?

To make it even more difficult, ingredient prices are constantly changing. The price for the ground beef in your burger just went up $3.00 a pound, decreasing your margins.

You now have the glorious task of going back into every recipe and changing the price for ground beef.

This happens after a week with almost every ingredient!

The Back Office Way

Hopefully, by now, you get the gist of this post.

Recipe Costing is SO important but also extremely difficult to maintain.

Back Office was developed for chefs, by chefs, to be the easiest and most reliable food costing tool on the market.

The less time you spend in our software the more time you have to do what you truly love!

Simply build your recipes in Back Office once. One time.

That’s it.

With every invoice that comes into the system, Back Office will automatically update the ingredient price showing you the true cost of the recipe today and the current margins based off your selling price!

This allows you to make many updates and revisions as a problem arises.

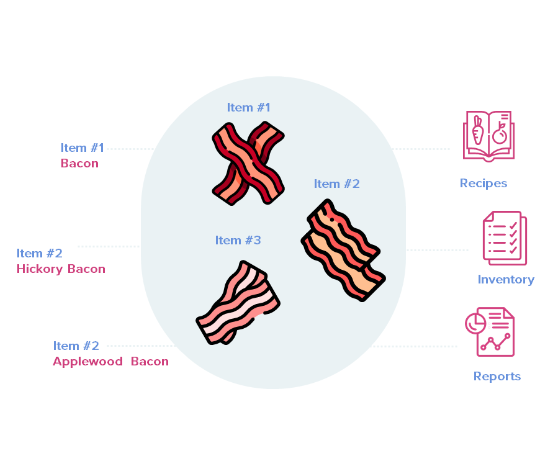

Buying a new ingredient or your vendor sent a substitution? No problem!

Back Office groups together substitute ingredients with the products you typically buy.

This means that regardless of whether you bought Hormel Apple Wood Smoked Bacon last week or Oscar Myer Apple Wood Smoked Bacon this week, Back Office will group these like items together and use them interchangeably in your recipes depending on which item you bought most recently, giving you the most up to date price for every menu item you build in Back Office!

Recipe costing is something that NEEDS to be done to ensure you are running a profitable business.

FINALLY, a recipe costing software resilient to substitutions and supplier changes.

Say goodbye to daily recipe maintenance!

Ready to put your recipe costing on autopilot and receive up-to-date food cost insights?

Reach out today and our team will be happy to discuss how Back Office can help!